Cookies

We and our business partners use technologies, including cookies.

Show detailsRealizations Wärtsilä 9L20 – 16...

Service date - Place - Customer:

From 2011 to 2023 years for Seatrade Griningen B.V Italy - reefer vessels - Europe - Central America route

Engines details:

Engine model: 920L, Power: 1600 kW, manufacturing year: 1998.

Range of works:

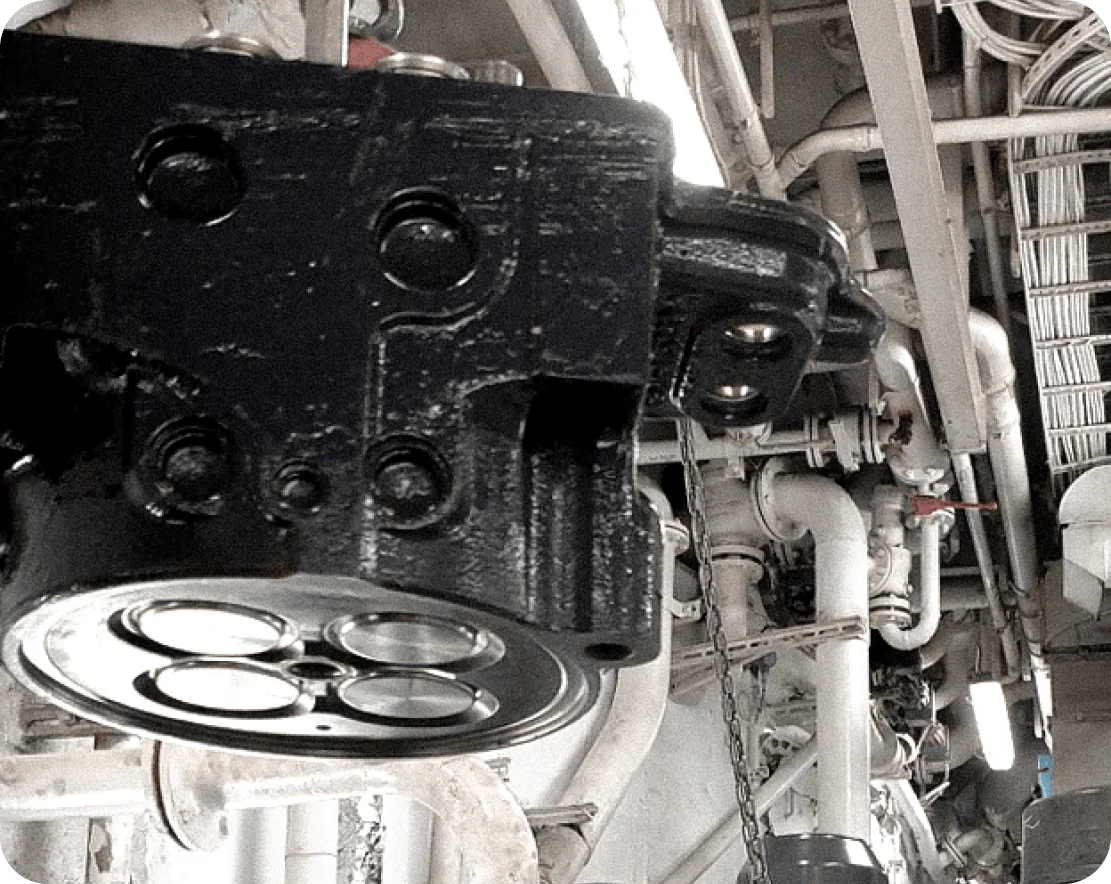

Regular overhauls of auxiliary engines #1, #2, #3, #4. All necessary activities related to overhaul intervals according Wartsila service manual 16000h, 24000h, 48000h and general overhaul 64000h.

Project Summary

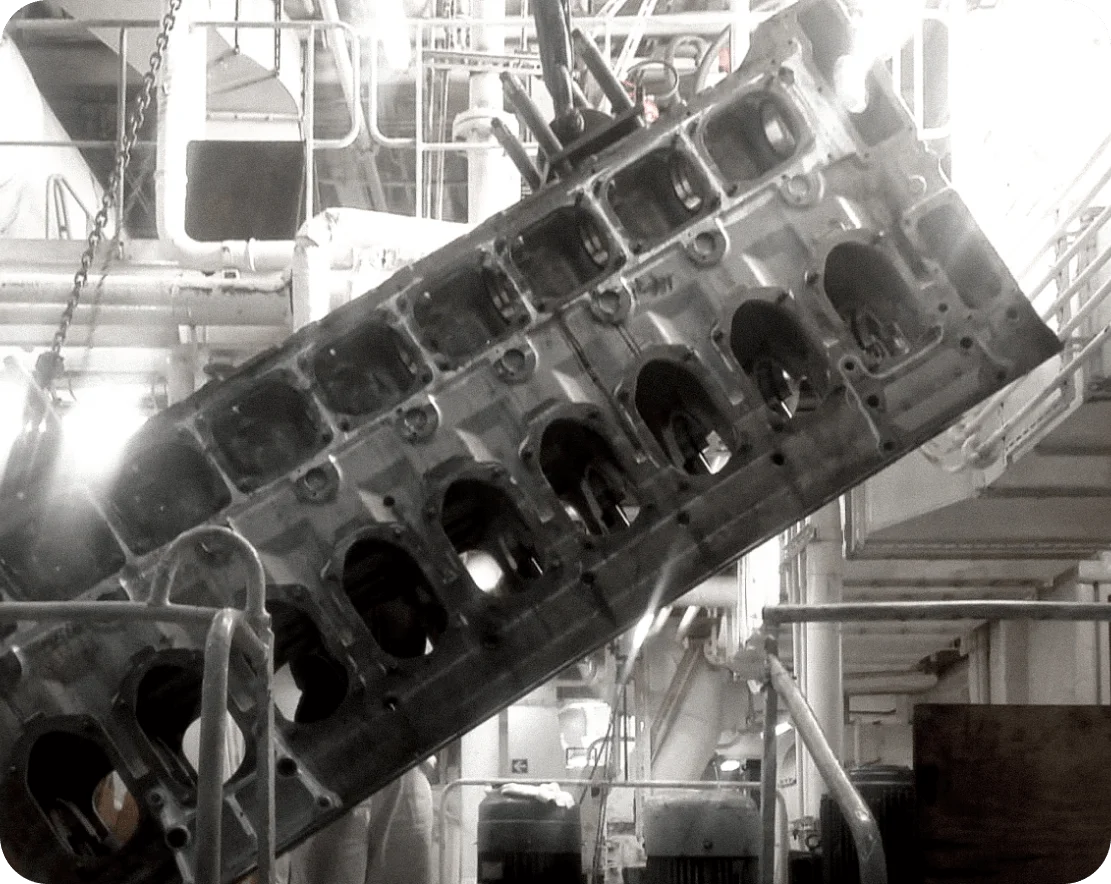

Our company has been providing overhauling services for Seatrade for many years. There are many ships and projects for which Seatrade engages us, but I would like to focus here on four ships that are under our constant care. We as a Servipol support those sister units with wide spectrum of smaller or more complex projects as for example complete overhaul of Wartsila 9L20 including engine block exchange. Every vessel has got four units of auxiliary engines, so in total we have sixteen which are under our constant care. Let’s have a closer look how do we make it done.

Running hours tell us when it’s a time to make an overhaul and that’s the moment when we enter ready and prepared for engine overhaul. Our first steps are always initially focused on inspecting spare parts and controlling the overall condition of the unit. During the dismantling it is essential to check every part and condition of the engine block, so we know where it is possible for us to look for potential damages. The visual phase it’s just a start of our task. After we finish this stage, it is a time for taking the parts for cleaning and measurements. After that we are sure what we rebuild our engine with checked and fine parts. Every detail is discussed, any minimal wear symptoms which occurred in any part we replace with new one. We make a shaft inspection and measurement then replace main bearings and connecting rod bearings. During assembling phase, we double check all operations, so we avoid any mistakes. It makes us perfectly sure that our job is well done, and the engine overhaul is done according engine manual. Testing stage ensures that another project is executed well. After running-in programme we are sure that our job has been performed perfectly and we gave the engine new life so it can run on its limits.

The

The

The

Let us take care of the engine repair

while we build the future together.