Cookies

We and our business partners use technologies, including cookies.

Show detailsRealizations STX engine MAN 16V32/40 en...

Service date - Place - Customer:

2023 Walvis Bay in Namibia - South Africa

Engines details:

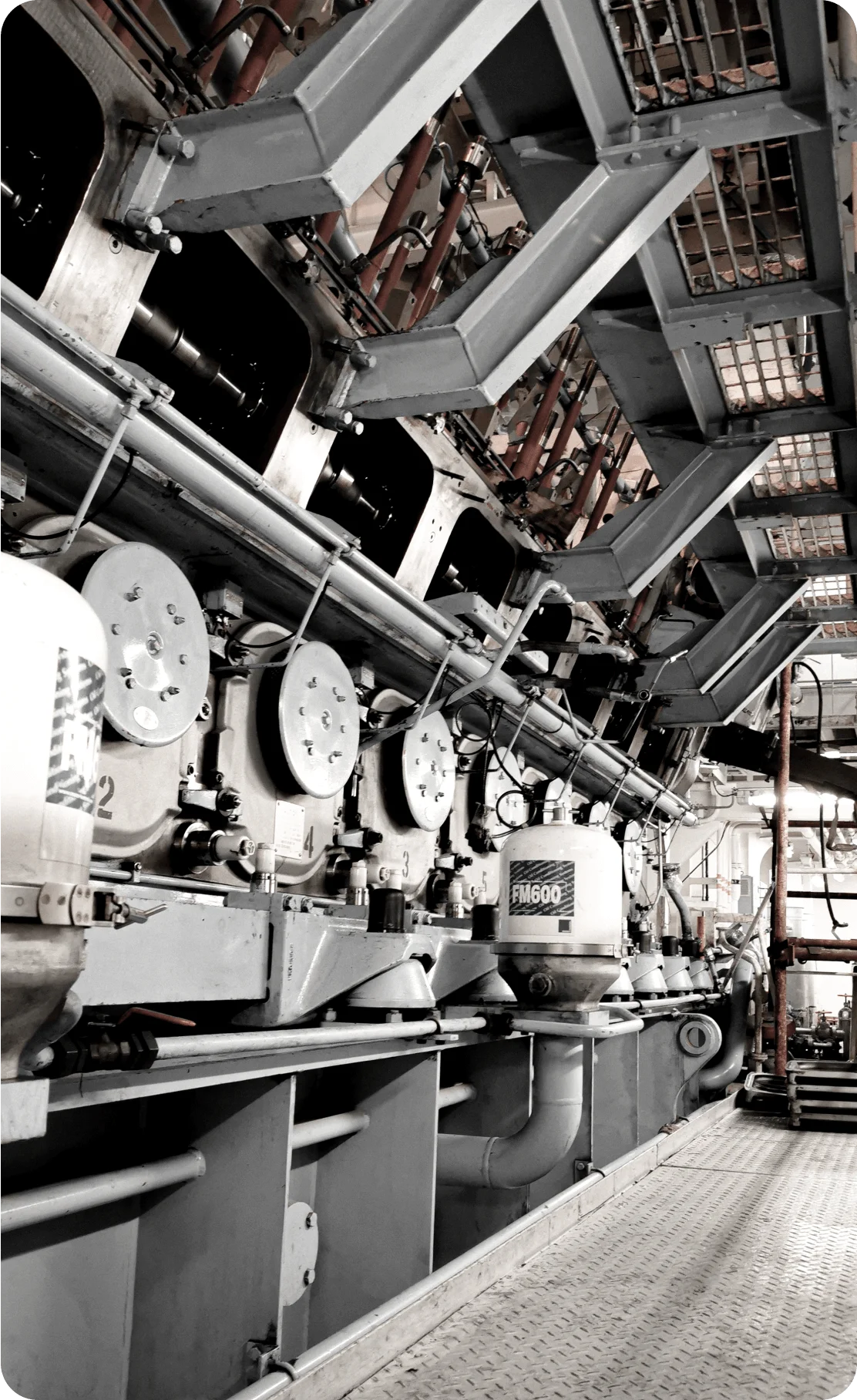

Engine model: STX- MAN 16V32/40- Engine: STX Engine MAN 16V32/40 2010, 720RPM 8750KVA 60HZ 11000 Voltage

Range of works:

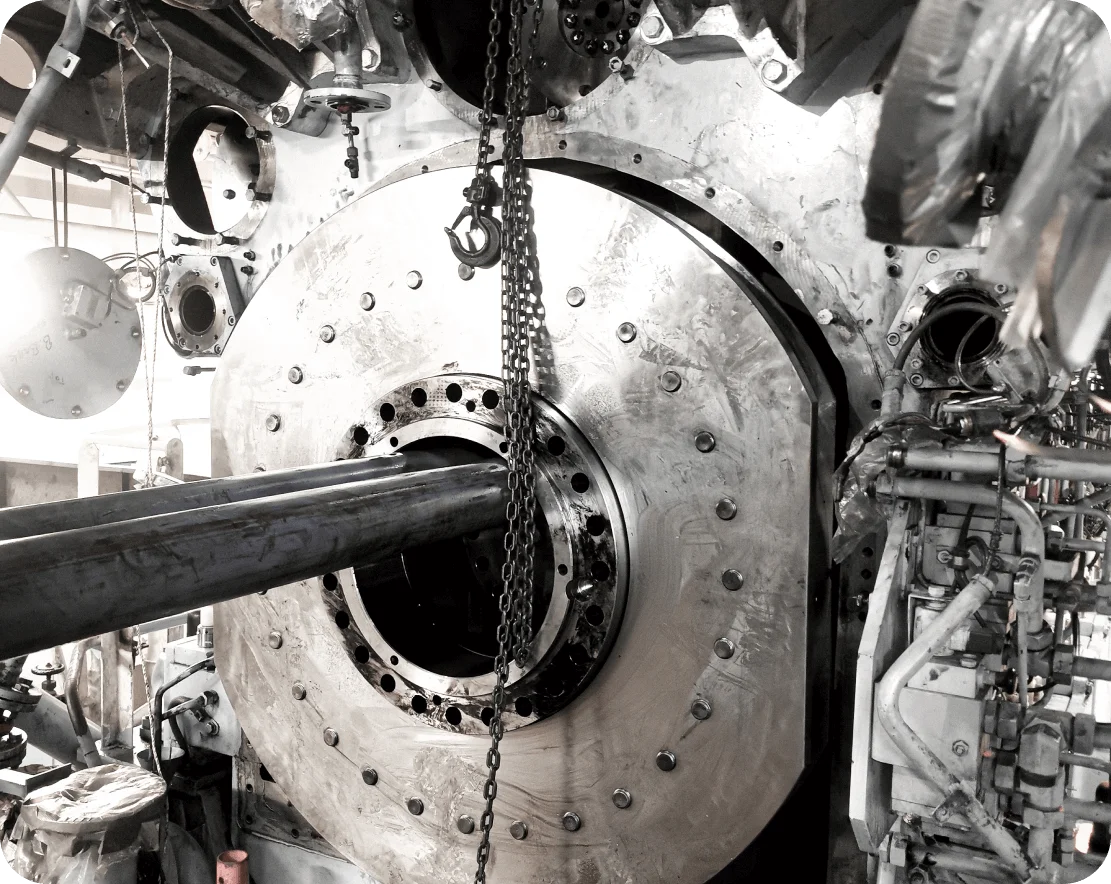

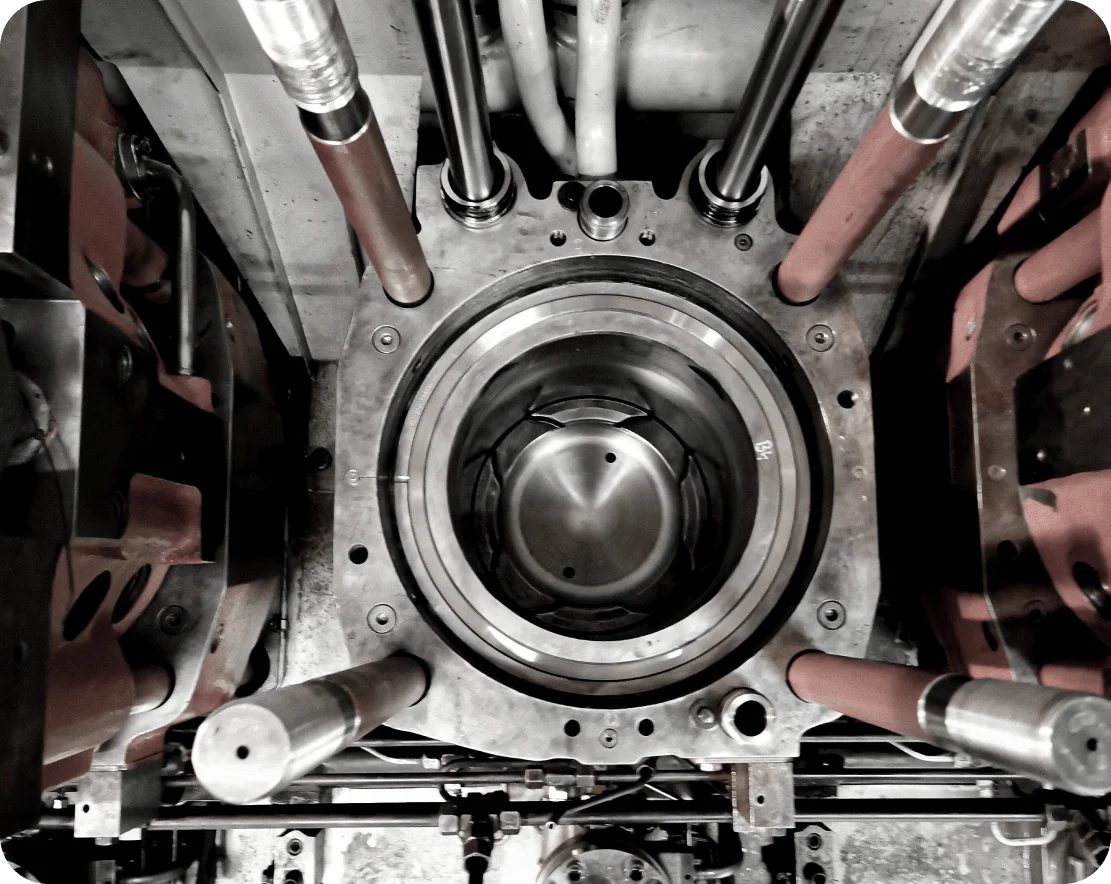

STX- MAN 16 V32/40 engine overhaul. Vibration Damper (overhaul by Goltens Rotterdam) installed with all the piping and overhauled pumps with new gaskets and orings a vibration damper, all the pump units, coolers and two turbochargers. All connecting rod bearings and main bearings replaced. Hydraulic fighting double checked with clock manometer gauge. Top camshaft mounted.

Project Summary:

Our team participated in overhaul of one of these motors. Drill ships have the functional ability of semi-submersible drilling rigs and also have a few unique features that separate them from all others, first being the ship-shaped design. A drillship has greater mobility and can move quickly under its own propulsion from drill site to drill site. This is what makes them so impressive.

We came to Walvis Bay in Namibia and took a voyage to South Africa to mantle the engine. Previous team dismantled it. It is so massive and demanding so it had to be split in two phases. Goltens company prepared all the parts in their workshop in Rotterdam. Our job required lots of skill and dedication. This engine has sixteen units of cylinder liners, pistons and cyliderheads, so it was time-consuming process which absorbed us completely. The customer wanted to overhaul a vibration damper, all the pump units, coolers and two turbochargers. All these jobs were executed by us. All connecting rod bearings and main bearings replaced. Hydraulic tighting double checked with clock manometer gauge. We didn’t encounter any major obstacles. After finalize our jobs vessel’s crew take the initiative, checked all of the installations, leaking tests and then proceeded to running-in programmed.

Another project finished with the success; this time we experienced the very peak of sea life industry. We are proud and satisfied that we are ready for all challenges and gave our commitment in place where requirements are the highest.

The

The

The

Let us take care of the engine repair

while we build the future together.